Products Details

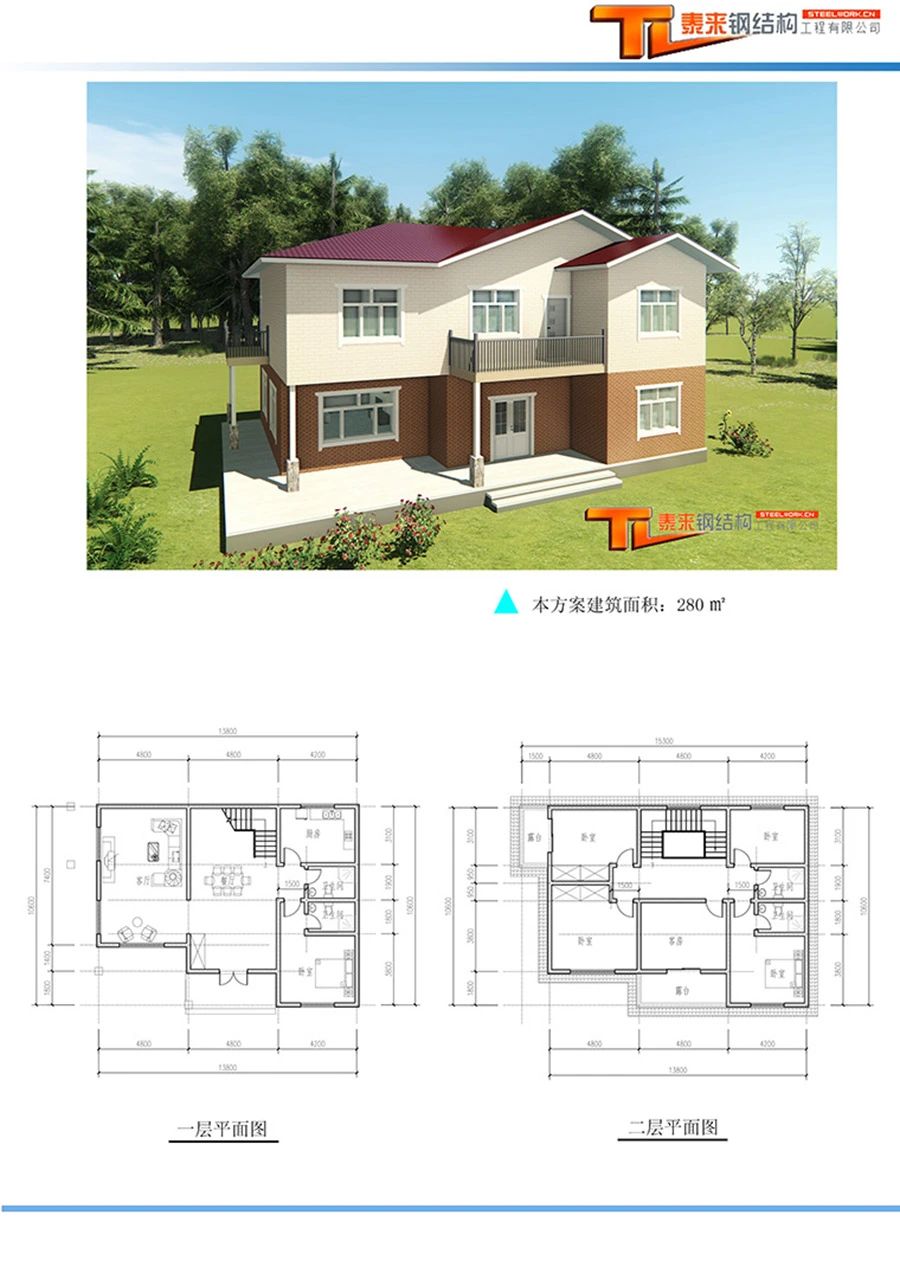

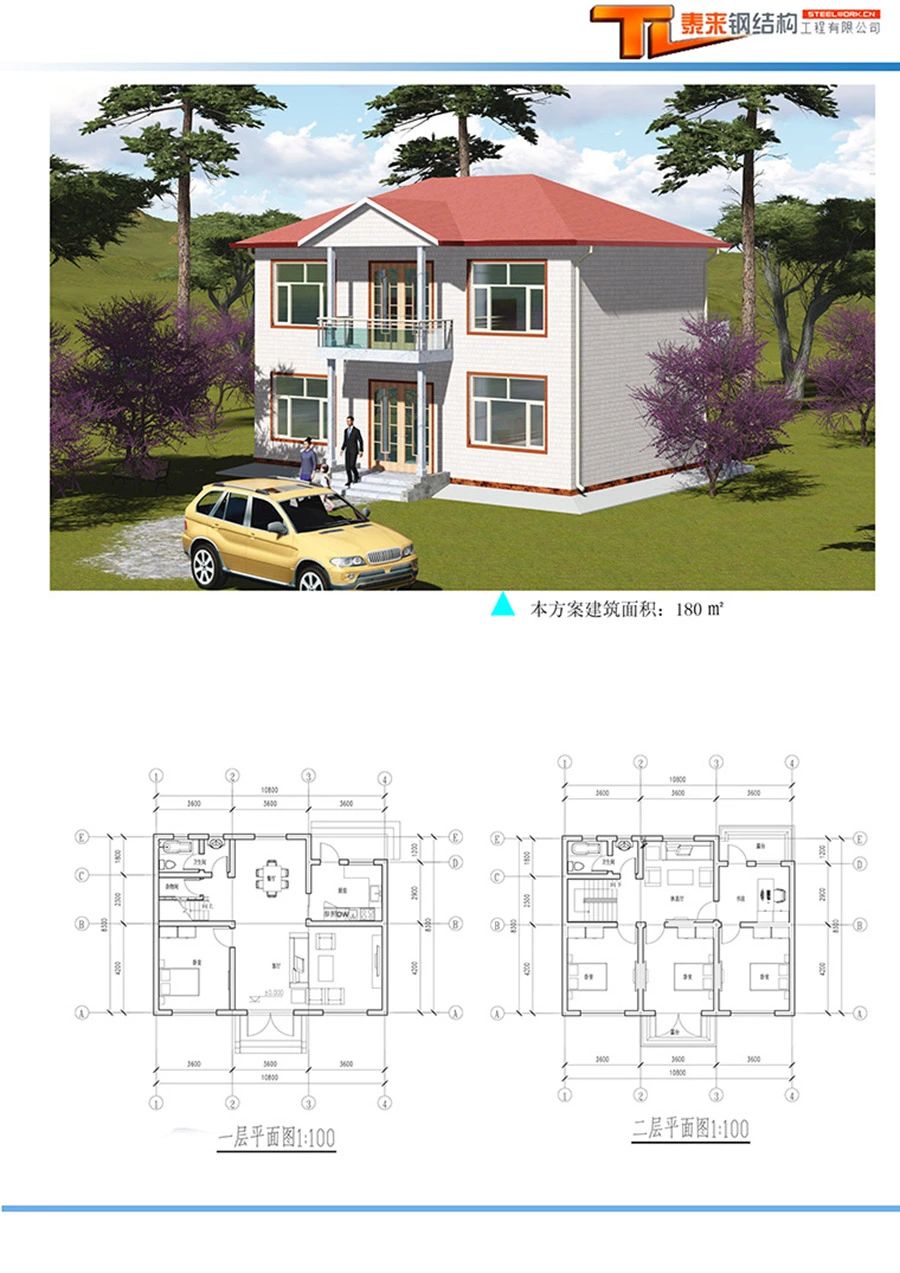

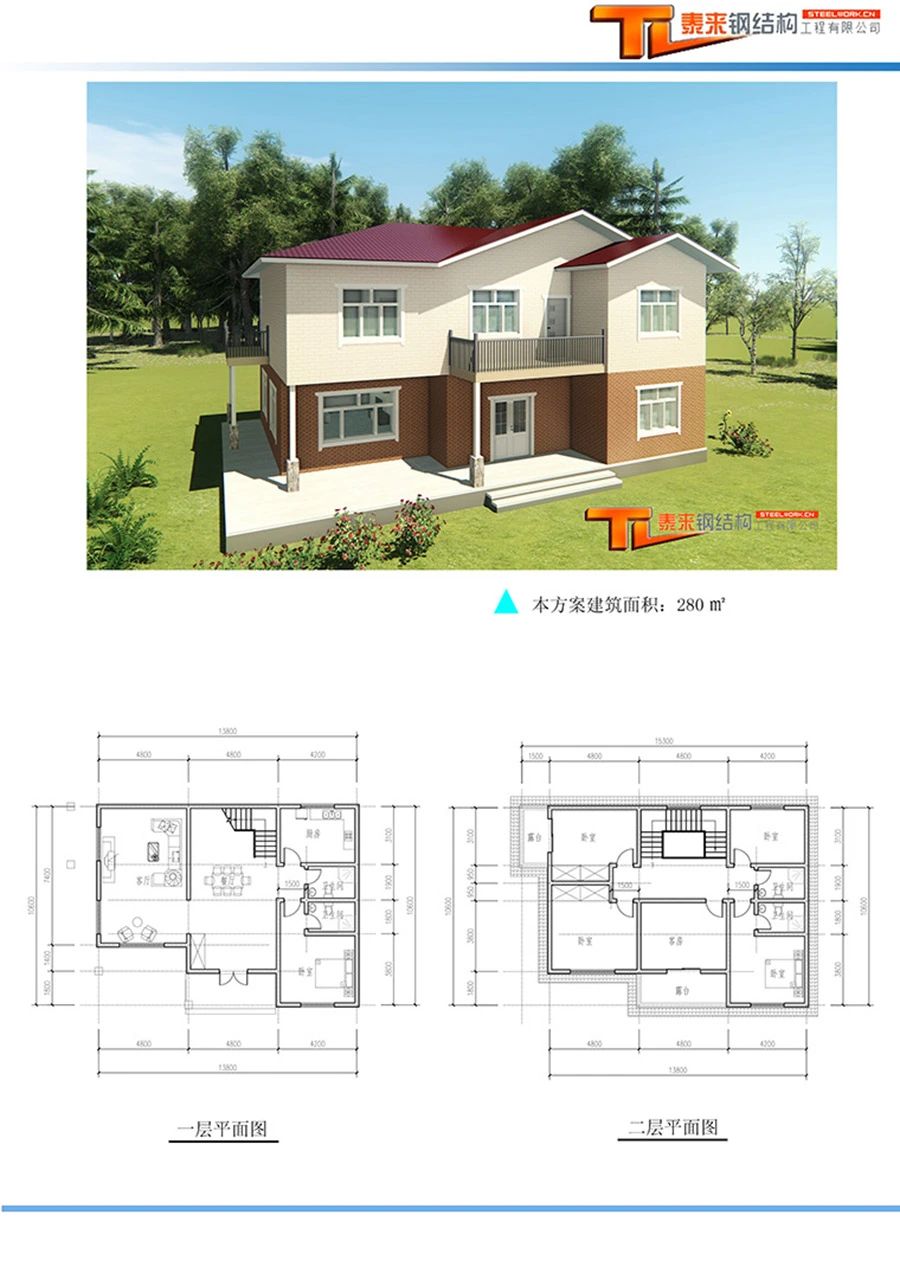

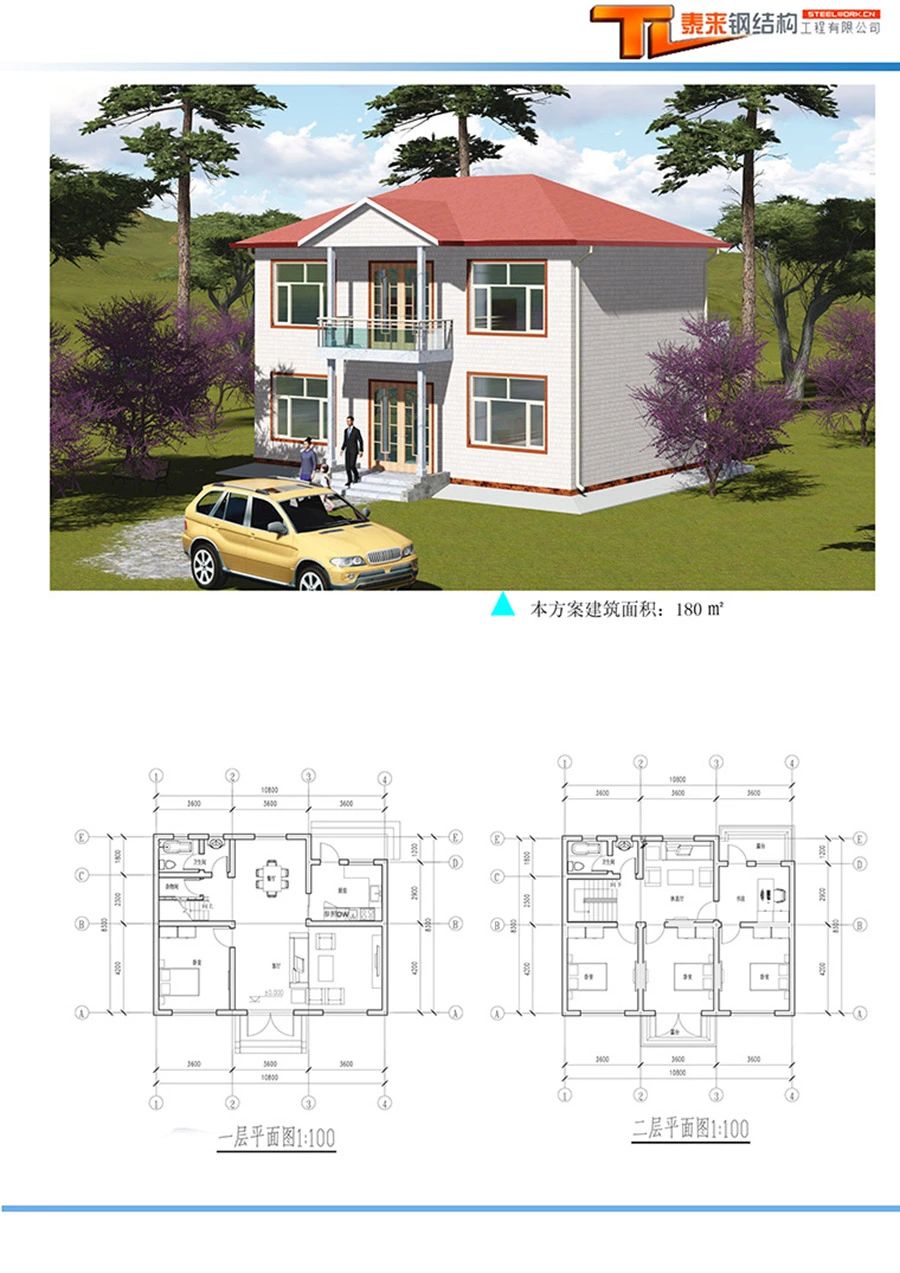

1. High structural stability 2. Easily assembled, disassembled and replaced. 3. Fast installation 4. Fit for any kinds of ground sill 5. Construction with little influence of climates 6. Personalized housing inside design 7. 92% usable floor area 8. Diverse appearance 9. Comfortable and energy saving 10. High recycle of the material 11. Wind and earthquake resist 12.Heat and sound insulation. The light steel villa is composed of structural system, ground system, floor system, wall system and roof system. Each system is composed of several unit modules. The unit modules are manufactured in the factory, and the unit modules are assembled on site. Light steel integrated houses can be disassembled and moved without damaging the land. It has realized the transformation from the "real estate" attribute of the house to the "movable property" attribute for thousands of years, and realized the complete separation of "real estate" and "real estate" for thousands of years. The on-site construction period of the light steel integrated house is 10%-30% of the traditional construction mode. The quality of the integrated house is more refined, realizing the transition from the centimeter-level error of the traditional building model to the millimeter-level error of factory manufacturing. The characteristics of Shunzhu light steel villa are: 1. Fire resistance: The fire resistance time of the wallboard can reach 5 hours, and the temperature of the back fire surface is only 46 degrees. 2. High strength: By adjusting the space plate thickness and built-in skeleton, the floor bearing capacity is 2.5-5.0KN/m2. 3. Thermal insulation/energy saving: wall thickness = thickness of thermal insulation layer, and the existing energy-saving technologies for building walls in China all adopt the practice of heating and thermal insulation layer on the outer wall. 4. Light weight: the self-weight of space board building is only 20% of that of masonry or cast-in-place structure building, and the weight is saved by 80%. 5. Sound insulation: 120mm thick sound insulation coefficient: ≥45 (dB). 6. Hydrophobicity: The unique cement foam core material of the space board has a closed cell rate of more than 95% and a water absorption rate of less than 2.5%, so it has good hydrophobicity. 7. Durability: safe service life of 90 years. The advantages of light steel integrated villas: Compared with traditional brick-concrete structure houses, the advantages of light steel integrated houses with new building materials system are irreplaceable: the wall thickness of general brick-concrete structure houses is mostly 240mm, while the prefabricated houses are in the same area. Below is less than 240mm. Indoor usable area ratio of integrated houses Traditional brick and concrete structures are much larger. Light steel integrated houses are light in weight, less wetland operations, and short construction periods. The thermal performance of the house is good, and the wall panel of the light steel integrated house is a foam color steel sandwich panel with heat insulation. Then, most of the building materials used in the light steel integrated house can be recycled and degraded, and the cost is low, and it is a green and environmentally friendly house. In particular, the brick-concrete structure is not environmentally friendly, and a large amount of clay is used, which destroys the ecology and reduces the cultivated land. Therefore, the technological breakthrough and application of light steel integrated houses will be long-term, and will change the traditional construction mode, making human The cost of living has become smaller and the living environment has become better. It can play an important role in environmental protection.

The light steel villa is composed of structural system, ground system, floor system, wall system and roof system. Each system is composed of several unit modules. The unit modules are manufactured in the factory, and the unit modules are assembled on site. Light steel integrated houses can be disassembled and moved without damaging the land. It has realized the transformation from the "real estate" attribute of the house to the "movable property" attribute for thousands of years, and realized the complete separation of "real estate" and "real estate" for thousands of years. The on-site construction period of the light steel integrated house is 10%-30% of the traditional construction mode. The quality of the integrated house is more refined, realizing the transition from the centimeter-level error of the traditional building model to the millimeter-level error of factory manufacturing. The characteristics of Shunzhu light steel villa are: 1. Fire resistance: The fire resistance time of the wallboard can reach 5 hours, and the temperature of the back fire surface is only 46 degrees. 2. High strength: By adjusting the space plate thickness and built-in skeleton, the floor bearing capacity is 2.5-5.0KN/m2. 3. Thermal insulation/energy saving: wall thickness = thickness of thermal insulation layer, and the existing energy-saving technologies for building walls in China all adopt the practice of heating and thermal insulation layer on the outer wall. 4. Light weight: the self-weight of space board building is only 20% of that of masonry or cast-in-place structure building, and the weight is saved by 80%. 5. Sound insulation: 120mm thick sound insulation coefficient: ≥45 (dB). 6. Hydrophobicity: The unique cement foam core material of the space board has a closed cell rate of more than 95% and a water absorption rate of less than 2.5%, so it has good hydrophobicity. 7. Durability: safe service life of 90 years. The advantages of light steel integrated villas: Compared with traditional brick-concrete structure houses, the advantages of light steel integrated houses with new building materials system are irreplaceable: the wall thickness of general brick-concrete structure houses is mostly 240mm, while the prefabricated houses are in the same area. Below is less than 240mm. Indoor usable area ratio of integrated houses Traditional brick and concrete structures are much larger. Light steel integrated houses are light in weight, less wetland operations, and short construction periods. The thermal performance of the house is good, and the wall panel of the light steel integrated house is a foam color steel sandwich panel with heat insulation. Then, most of the building materials used in the light steel integrated house can be recycled and degraded, and the cost is low, and it is a green and environmentally friendly house. In particular, the brick-concrete structure is not environmentally friendly, and a large amount of clay is used, which destroys the ecology and reduces the cultivated land. Therefore, the technological breakthrough and application of light steel integrated houses will be long-term, and will change the traditional construction mode, making human The cost of living has become smaller and the living environment has become better. It can play an important role in environmental protection.

If you have a drawing,we can quote for you accordingly If you don’t have a drawing,but interested in our steel structure building,kinldy provide the details as following 1.The size:length/width/height/eave height? 2.The location of the building and its usage. 3.The local climate,such as:wind load,rain load,snow load? 4.The doors and windows size,quantity,position? 5.What kind of panel do you like?sandwich panel or steel sheet panel? 6.Do you need crane beam inside the building?if need,what’s the capacity? 7.Do you need skylight? 8.Do you have any other requirements?

If you have a drawing,we can quote for you accordingly If you don’t have a drawing,but interested in our steel structure building,kinldy provide the details as following 1.The size:length/width/height/eave height? 2.The location of the building and its usage. 3.The local climate,such as:wind load,rain load,snow load? 4.The doors and windows size,quantity,position? 5.What kind of panel do you like?sandwich panel or steel sheet panel? 6.Do you need crane beam inside the building?if need,what’s the capacity? 7.Do you need skylight? 8.Do you have any other requirements? Established in year 2003, Weifang Tailai Steel Structure Engineering Co., Ltd, with registered capital 16 million RMB, located in Dongcheng Development district, Linqu County,Taila is one of the largest steel structure related produsts manufacturer in China, specializes in construction design, manufacturing, instruction project construction, steel structure material etc. ,has the most advanced product line for H section beam, box column, truss frame, steel grid, light steel keel structure. Tailai also has the high precision 3-D CNC drilling machine, Z & C type purlin machine,multi-model color steel tile machine, floor deck machine, and fully equipped inspection line. Tailai has a very strong tecnology strength,including employee over 180,three senior engineers,20 engineers,one level A registered structural engineer,10 level A registered architectural engineers,50 level B registered architectural engineer,over 50 technicians. After years of development, now have 3 factories and 8 production lines. The factory area is more than 30000 square meters. and has been awarded ISO 9001 certificate and PHI Passive House Certificate. Exporting to more than 50 countries. Based on our hard work and wonderful group spirit, we will promote and popularize our products in more countries.

Established in year 2003, Weifang Tailai Steel Structure Engineering Co., Ltd, with registered capital 16 million RMB, located in Dongcheng Development district, Linqu County,Taila is one of the largest steel structure related produsts manufacturer in China, specializes in construction design, manufacturing, instruction project construction, steel structure material etc. ,has the most advanced product line for H section beam, box column, truss frame, steel grid, light steel keel structure. Tailai also has the high precision 3-D CNC drilling machine, Z & C type purlin machine,multi-model color steel tile machine, floor deck machine, and fully equipped inspection line. Tailai has a very strong tecnology strength,including employee over 180,three senior engineers,20 engineers,one level A registered structural engineer,10 level A registered architectural engineers,50 level B registered architectural engineer,over 50 technicians. After years of development, now have 3 factories and 8 production lines. The factory area is more than 30000 square meters. and has been awarded ISO 9001 certificate and PHI Passive House Certificate. Exporting to more than 50 countries. Based on our hard work and wonderful group spirit, we will promote and popularize our products in more countries.

Metal Frame Structure,

Metal Shop Building,

China Steel Structure Workshop,

Steel Office,

Chicken Farm Building,

Customized Metal Building,

Steel Showroom,

Metal Steel Hangar,

Steel Structure Construction,

Steel Frame Shop,

The light steel villa is composed of structural system, ground system, floor system, wall system and roof system. Each system is composed of several unit modules. The unit modules are manufactured in the factory, and the unit modules are assembled on site. Light steel integrated houses can be disassembled and moved without damaging the land. It has realized the transformation from the "real estate" attribute of the house to the "movable property" attribute for thousands of years, and realized the complete separation of "real estate" and "real estate" for thousands of years. The on-site construction period of the light steel integrated house is 10%-30% of the traditional construction mode. The quality of the integrated house is more refined, realizing the transition from the centimeter-level error of the traditional building model to the millimeter-level error of factory manufacturing. The characteristics of Shunzhu light steel villa are: 1. Fire resistance: The fire resistance time of the wallboard can reach 5 hours, and the temperature of the back fire surface is only 46 degrees. 2. High strength: By adjusting the space plate thickness and built-in skeleton, the floor bearing capacity is 2.5-5.0KN/m2. 3. Thermal insulation/energy saving: wall thickness = thickness of thermal insulation layer, and the existing energy-saving technologies for building walls in China all adopt the practice of heating and thermal insulation layer on the outer wall. 4. Light weight: the self-weight of space board building is only 20% of that of masonry or cast-in-place structure building, and the weight is saved by 80%. 5. Sound insulation: 120mm thick sound insulation coefficient: ≥45 (dB). 6. Hydrophobicity: The unique cement foam core material of the space board has a closed cell rate of more than 95% and a water absorption rate of less than 2.5%, so it has good hydrophobicity. 7. Durability: safe service life of 90 years. The advantages of light steel integrated villas: Compared with traditional brick-concrete structure houses, the advantages of light steel integrated houses with new building materials system are irreplaceable: the wall thickness of general brick-concrete structure houses is mostly 240mm, while the prefabricated houses are in the same area. Below is less than 240mm. Indoor usable area ratio of integrated houses Traditional brick and concrete structures are much larger. Light steel integrated houses are light in weight, less wetland operations, and short construction periods. The thermal performance of the house is good, and the wall panel of the light steel integrated house is a foam color steel sandwich panel with heat insulation. Then, most of the building materials used in the light steel integrated house can be recycled and degraded, and the cost is low, and it is a green and environmentally friendly house. In particular, the brick-concrete structure is not environmentally friendly, and a large amount of clay is used, which destroys the ecology and reduces the cultivated land. Therefore, the technological breakthrough and application of light steel integrated houses will be long-term, and will change the traditional construction mode, making human The cost of living has become smaller and the living environment has become better. It can play an important role in environmental protection.

The light steel villa is composed of structural system, ground system, floor system, wall system and roof system. Each system is composed of several unit modules. The unit modules are manufactured in the factory, and the unit modules are assembled on site. Light steel integrated houses can be disassembled and moved without damaging the land. It has realized the transformation from the "real estate" attribute of the house to the "movable property" attribute for thousands of years, and realized the complete separation of "real estate" and "real estate" for thousands of years. The on-site construction period of the light steel integrated house is 10%-30% of the traditional construction mode. The quality of the integrated house is more refined, realizing the transition from the centimeter-level error of the traditional building model to the millimeter-level error of factory manufacturing. The characteristics of Shunzhu light steel villa are: 1. Fire resistance: The fire resistance time of the wallboard can reach 5 hours, and the temperature of the back fire surface is only 46 degrees. 2. High strength: By adjusting the space plate thickness and built-in skeleton, the floor bearing capacity is 2.5-5.0KN/m2. 3. Thermal insulation/energy saving: wall thickness = thickness of thermal insulation layer, and the existing energy-saving technologies for building walls in China all adopt the practice of heating and thermal insulation layer on the outer wall. 4. Light weight: the self-weight of space board building is only 20% of that of masonry or cast-in-place structure building, and the weight is saved by 80%. 5. Sound insulation: 120mm thick sound insulation coefficient: ≥45 (dB). 6. Hydrophobicity: The unique cement foam core material of the space board has a closed cell rate of more than 95% and a water absorption rate of less than 2.5%, so it has good hydrophobicity. 7. Durability: safe service life of 90 years. The advantages of light steel integrated villas: Compared with traditional brick-concrete structure houses, the advantages of light steel integrated houses with new building materials system are irreplaceable: the wall thickness of general brick-concrete structure houses is mostly 240mm, while the prefabricated houses are in the same area. Below is less than 240mm. Indoor usable area ratio of integrated houses Traditional brick and concrete structures are much larger. Light steel integrated houses are light in weight, less wetland operations, and short construction periods. The thermal performance of the house is good, and the wall panel of the light steel integrated house is a foam color steel sandwich panel with heat insulation. Then, most of the building materials used in the light steel integrated house can be recycled and degraded, and the cost is low, and it is a green and environmentally friendly house. In particular, the brick-concrete structure is not environmentally friendly, and a large amount of clay is used, which destroys the ecology and reduces the cultivated land. Therefore, the technological breakthrough and application of light steel integrated houses will be long-term, and will change the traditional construction mode, making human The cost of living has become smaller and the living environment has become better. It can play an important role in environmental protection.

If you have a drawing,we can quote for you accordingly If you don’t have a drawing,but interested in our steel structure building,kinldy provide the details as following 1.The size:length/width/height/eave height? 2.The location of the building and its usage. 3.The local climate,such as:wind load,rain load,snow load? 4.The doors and windows size,quantity,position? 5.What kind of panel do you like?sandwich panel or steel sheet panel? 6.Do you need crane beam inside the building?if need,what’s the capacity? 7.Do you need skylight? 8.Do you have any other requirements?

If you have a drawing,we can quote for you accordingly If you don’t have a drawing,but interested in our steel structure building,kinldy provide the details as following 1.The size:length/width/height/eave height? 2.The location of the building and its usage. 3.The local climate,such as:wind load,rain load,snow load? 4.The doors and windows size,quantity,position? 5.What kind of panel do you like?sandwich panel or steel sheet panel? 6.Do you need crane beam inside the building?if need,what’s the capacity? 7.Do you need skylight? 8.Do you have any other requirements? Established in year 2003, Weifang Tailai Steel Structure Engineering Co., Ltd, with registered capital 16 million RMB, located in Dongcheng Development district, Linqu County,Taila is one of the largest steel structure related produsts manufacturer in China, specializes in construction design, manufacturing, instruction project construction, steel structure material etc. ,has the most advanced product line for H section beam, box column, truss frame, steel grid, light steel keel structure. Tailai also has the high precision 3-D CNC drilling machine, Z & C type purlin machine,multi-model color steel tile machine, floor deck machine, and fully equipped inspection line. Tailai has a very strong tecnology strength,including employee over 180,three senior engineers,20 engineers,one level A registered structural engineer,10 level A registered architectural engineers,50 level B registered architectural engineer,over 50 technicians. After years of development, now have 3 factories and 8 production lines. The factory area is more than 30000 square meters. and has been awarded ISO 9001 certificate and PHI Passive House Certificate. Exporting to more than 50 countries. Based on our hard work and wonderful group spirit, we will promote and popularize our products in more countries.

Established in year 2003, Weifang Tailai Steel Structure Engineering Co., Ltd, with registered capital 16 million RMB, located in Dongcheng Development district, Linqu County,Taila is one of the largest steel structure related produsts manufacturer in China, specializes in construction design, manufacturing, instruction project construction, steel structure material etc. ,has the most advanced product line for H section beam, box column, truss frame, steel grid, light steel keel structure. Tailai also has the high precision 3-D CNC drilling machine, Z & C type purlin machine,multi-model color steel tile machine, floor deck machine, and fully equipped inspection line. Tailai has a very strong tecnology strength,including employee over 180,three senior engineers,20 engineers,one level A registered structural engineer,10 level A registered architectural engineers,50 level B registered architectural engineer,over 50 technicians. After years of development, now have 3 factories and 8 production lines. The factory area is more than 30000 square meters. and has been awarded ISO 9001 certificate and PHI Passive House Certificate. Exporting to more than 50 countries. Based on our hard work and wonderful group spirit, we will promote and popularize our products in more countries.